Production automation

У виробничому бізнесі відсутність чіткої координації між відділами, розпорошеність даних, ручне управління замовленнями та складськими залишками призводить до втрат, затримок і зниження прибутковості. ERP&CRM для виробництва Odoo дозволяє централізувати управління процесами та гарантувати прозорість на всіх етапах.

Які труднощі виробництва вирішує ERP-система?

In the manufacturing environment, companies face a number of challenges that can hinder development and make it difficult to scale. Therefore, automation of the production process is an important factor that helps to solve such business problems:

- Unstructured management of production processes. Обробка замовлень, їх передача на виробництво, контроль виконання та логістика часто відбуваються хаотично. Odoo ERP дозволяє впорядкувати ці етапи, скоротити час на виконання задач і уникнути помилок.

- Weak sales and lack of resources for online trading. Запуск продажів на маркетплейсах або власному сайті потребує часу, персоналу та технічної підтримки. ERP система для виробництва автоматизує процеси, дозволяючи швидко об’єднувати торгові платформи й ефективно керувати замовленнями.

- Loss of customer requests through different channels. Orders come from messengers, social networks, and chats, and as a result, they can get lost. The program combines all communication channels into a single system, providing full control over each request.

An ERP system for manufacturing allows you to streamline your business, improve customer service, and increase profitability. It helps to overcome chaos, reduce losses, and create a clear management structure.

Why automate your production process with Odoo?

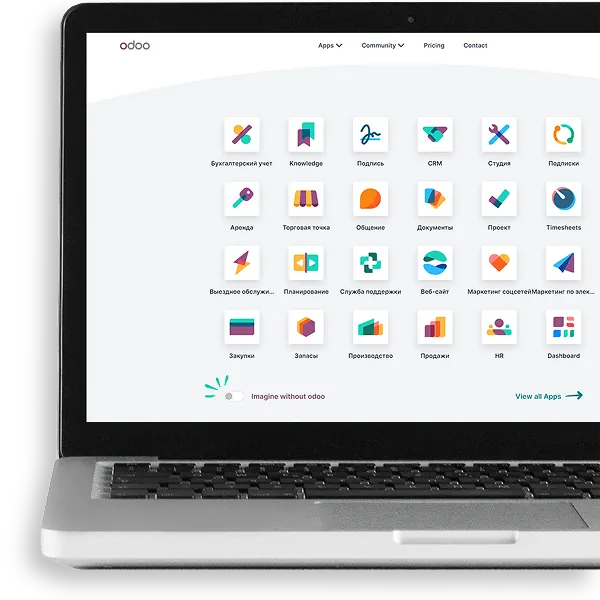

Odoo ERP is a system that not only automates processes, but also provides in-depth analytics and flexible management. It has advantages that can significantly change the way you do business:

Rationalization of production operations. Thanks to the implementation of CRM, you can automate routine tasks, reduce the time it takes to complete them, and increase productivity.

Increase transparency in the supply chain. Automation of production processes allows for continuous monitoring of all stages of delivery, which minimizes the risk of delays and ensures stability in logistics processes.

Deepening customer engagement. As a result of collecting and analyzing ERP data, the Odoo system helps to form an individual approach to each client.

Optimization of warehouse inventory management. ERP for manufacturing provides accurate tracking of warehouse balances, which helps to avoid overstocks or shortages.

Впровадження Odoo — важливий крок до цифрової трансформації бізнесу. Система допомагає компанії бути більш гнучкою та забезпечувати високий рівень обслуговування клієнтів.

ERP implementation in production - solutions from ToDo

Комплексна автоматизація виробництва означає здатність ефективно керувати щоденними завданнями. Коли команда обмежена, а кількість задач постійно зростає, ERP-система Odoo стає незамінним інструментом для впорядкування процесів. Компанія ToDo пропонує впровадження програмного забезпечення, яке адаптується до реальних умов вашого бізнесу. Ми є офіційними партнерами по впровадженню системи Odoo в Україні.

Ви отримаєте програму для виробництва, котра працює швидко, точно та без втрат часу. Odoo вдало підлаштовується під ваші рішення, підтримуючи вже налагоджені процеси. Ми гарантуємо повний супровід: пояснюємо кожен етап, навчаємо команду, надаємо технічну підтримку.

Want to try Odoo and learn more?

Frequently asked questions

Why does manufacturing need an ERP system?

На відміну від інших галузей, виробництво потребує чіткого контролю над запасами, гнучкого управління ризиками й ефективної взаємодії з клієнтами. Тому ERP&CRM-система є корисним інструментом, який допомагає оптимізувати внутрішні процеси.

Automation of the company's production contributes to well-coordinated and predictable work, covering all aspects: from warehouse monitoring to increasing customer loyalty. As a result, the company gains a competitive advantage that contributes to sustainable growth.

How long does it take to implement ERP in production

The duration of ERP production planning implementation varies depending on a number of individual parameters. Each production facility has its own peculiarities, so the time for system integration is determined by the following factors:

- Business type and scale. The more complex the company's structure, the more time it takes to set up and adapt the system.

- Specifics of internal processes. If your business has non-standard or multi-level processes, integration will require additional customization.

- Number of staff. A large team needs more time to train, test, and adapt to the new system.

Впровадження системи може займати від тижня до кількох місяців. Цей термін скорочується або продовжується залежно від підготовки компанії та вибраної стратегії інтеграції. Вартість Odoo залежить від кількості користувачів і модулів, які підключаються. Чим більше функцій потрібно, тим вища буде ціна. Важливу роль відіграє й спосіб розгортання: у хмарі або на власному сервері. Так ви платите не просто за програму, а за набір інструментів, які підлаштовуються під ваш бізнес.